Explosion Proof Threading Box

ATEX Approved

Explosion Proof Threading Box

Applicable Scope

1. Aluminium alloy die-casting shell, after high-speed shot peening, the surface is subject to high-voltage

electrostatic spraying;

2. It is applicable to the places in Zone 1 and Zone 2 of explosive gas environment;

3. It is applicable to the places in Zone 21 and 22 of combustible dust environment;

4. Suitable for IIA, IIB and IIC explosive gas environment;

5. Applicable to T1-T6 temperature group;

6. It is applicable to dangerous environments such as oil exploitation, oil refining, chemical industry, gas

station, offshore oil platforms, oil tankers, metal processing, etc. as the connection and turning direction

change of steel pipe wiring.

Features

Explosion-proof Transfer Switch BHZ51

Applicable Environment:

Applicable to Zone 1 and Zone 2 hazardous locations

Applicable to IIA, IIB, IIC explosive gas environments

Temperature group: T1-T6

Indoor, outdoor

Features

The shell is made of ZL102 aluminium alloy die-casting or steel plate welding, and the surface is

high-voltage electrostatic sprayed;

Voltage 220V-380V, current 10-63A. It is used as a power supply introduction switch in the electrical

circuit and can control the start, stop, speed change, and steering of the motor

Steel pipe or cable wiring is acceptable

Technical Parameters

Explosion proof Mark Ex db IIC Gb/ Ex eb IIC Gb / Ex tb IIIC T80°C Db

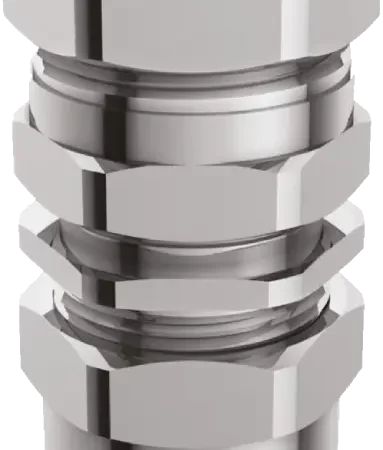

Thread specifications “G1/2-G4”、“NPT1/2-NPT4”、“M20-M110” Various sizes of threads

for users to choose from

Protection level IP66

1. Aluminium alloy die-casting shell, after high-speed

shot peening, the surface is subject to high-voltage

electrostatic spraying;

2. Exposed stainless steel fasteners with high anti-corrosion performance;

3. There are many ways and specifications for the inlet

and outlet.

Reviews

There are no reviews yet.